[OUR PROJECTS ]

Proof in Every Brick. Vision in Every Build.

Every project we deliver, from schools and campuses to industries and urban solutions is built with the same clarity of purpose: to raise the benchmark of construction. Our work is not just about completing structures, but about creating lasting confidence through performance, sustainability, and vision that few can match.

Scroll to Continue

[OUR PROJECTS ]

OUR PROJECTS

Crores worth of completed construction — from urban villas to institutional campuses.

Over 400,000 sq. ft. built using sustainable principles and local craftsmanship.

Featured Project: GIIS Bannerghatta, Bangalore

Reimagining Learning Through Nature

Overview:

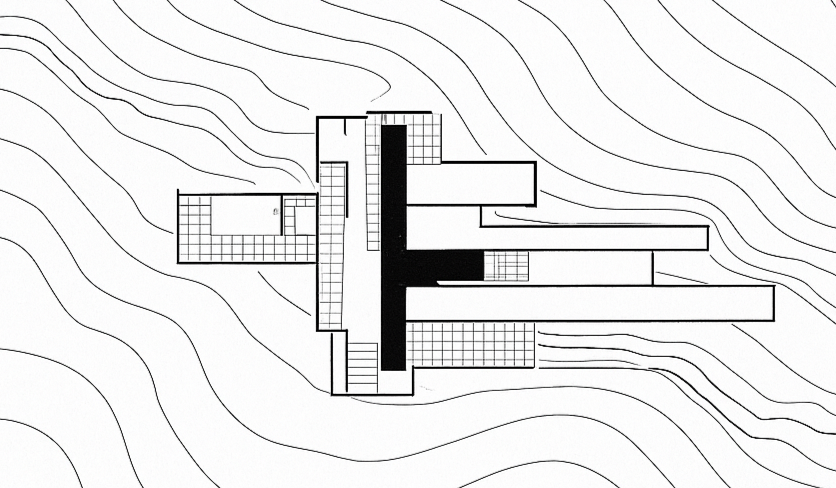

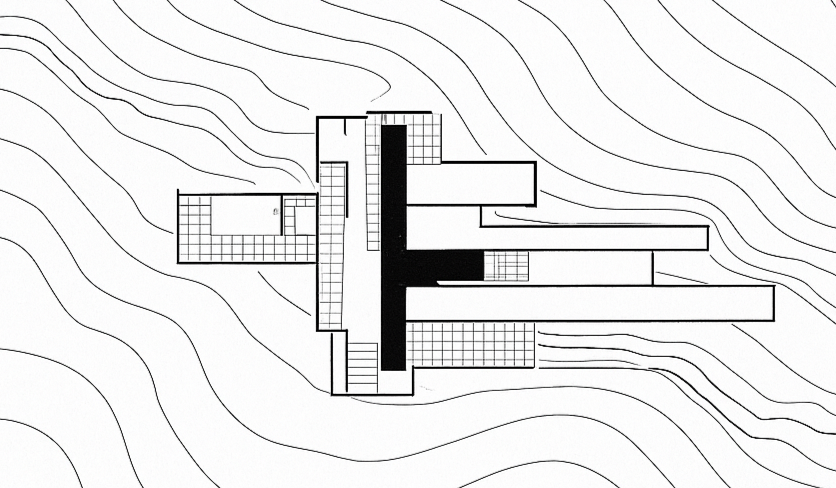

Global Indian International School’s new campus nestles alongside a natural park and embraces biophilic design to reconnect students with the outdoors. Only 20% of the site is built up, 80% remains open, landscaped green space.

Key Sustainability Initiatives:

- On‑Site CSEB Manufacturing

Compressed Stabilized Earth Blocks (CSEBs) for all walls, zero factory emissions, deep thermal mass. - Rainwater Recharge & Harvesting

All roof runoff is routed through piping into recharge pits; overflow feeds the on‑site well. - Daylighting Strategy

Building orientation, clerestories, and light wells ensure abundant natural light - boosting health, focus, and energy savings. - PEC ROAD

- Evaporative Cooling and stack ventilation

This campus isn’t just a school, it’s a living lab in sustainable design, resource efficiency, and well‑being.

Jubilant FoodWorks Ltd. - South India Commissary

Jubilant FoodWorks, the parent company of Domino’s Pizza in India, commissioned a central commissary to serve all its outlets across Karnataka, Tamil Nadu, Andhra Pradesh, and Kerala. The facility required exacting standards of hygiene, thermal performance, and workflow optimization to support high-volume food production and logistics.

GSL executed the project to strict technical specifications, meeting all functional and regulatory benchmarks. The result: a reliable, high-efficiency facility delivered on time and to full client satisfaction.

Wieland Metals India Pvt. Ltd. Copper Slitting Facility, Bangalore

Wieland Metals, a global leader in copper and copper alloys with over a century of legacy, selected GSL Corp to build their first plant in India, a slitting centre in Bangalore. The selection followed multiple rounds of technical evaluation and detailed discussions with their global and Indian teams.

The facility was executed to meet stringent German industrial standards, aligning with Wieland’s exacting quality benchmarks. This project reflects not just cross-border execution capability, but trust built through consistency, clarity, and craft.

Alltech Biotechnology Pvt. Ltd. Feed Supplement Production Facility

Alltech, headquartered in Lexington, Kentucky, commissioned GSL Corp to construct a multi-storey plant in India to manufacture natural feed supplements for the poultry and dairy industries.

The facility features 24 ft clear height, celestial windows for daylight harvesting, and a 7-inch roof slab topped with 4 inches of waterproofing and screed concrete, ensuring long-term thermal insulation and durability. Other sustainable features include rainwater harvesting & recharge, west-side landscaping, energy-efficient lighting, and 40+ ft column spacing for seamless workflow.

Mersen India Pvt. Ltd. Multi-Storey Industrial Facility, Bangalore

Mersen, a French multinational with global expertise in high-temperature solutions and electrical safety systems, entrusted GSL Corp to build a high-spec industrial facility tailored to their operational needs.

We delivered a multi-storey plant featuring 24 ft clear height, thermal insulation, and energy-efficient lighting, with structural capacity of 2 tons/sq.m on the ground floor and 1 ton/sq.m on the first. Additional features include rainwater harvesting, south–west landscaping for heat mitigation, and 40 ft+ column spacing for unbroken internal flow.

Carl Zeiss

Engineered for Accuracy, Built for Efficiency

Carl Zeiss, a global leader in optical and optoelectronic technology, partnered with GSL Corp to deliver a state-of-the-art multi-storey production facility in India. Designed to support high-precision manufacturing, the building incorporates a 40+ ft column grid to maximise floor space and streamline operations. The facility’s 24 ft clear height and clerestory windows bring in abundant natural light and promote ventilation, reducing dependence on artificial lighting. A 7-inch roof slab finished with 4 inches of screed concrete and waterproofing ensures robust thermal insulation and long-term weather protection.

Sustainability was integral to the design:

rainwater harvesting with groundwater recharge enhances water resilience; landscaping along the western elevation reduces heat gain; and energy-efficient lighting cuts operational energy use. Every element of the build—from structure to services—was optimised for durability, occupant comfort, and operational efficiency.

OWIS, Sarjapur

OWIS Sarjapur entrusted GSL Construction with the addition of a full extra floor as a brownfield project. executed while the school remained fully operational. This required not just technical precision, but a careful orchestration of work schedules, safety protocols, and noise management to ensure zero disruption to ongoing classes.

The project was completed within 8 months, without a single interruption to the school’s academic calendar. A testament to both our planning discipline and on-site execution strength.

Switchgear & Control Technics Private limited, Bommasandra

For their Bommasandra facility, GSL was entrusted with transforming an existing industrial unit into a modern, high-performance manufacturing plant. Working within an aggressive timeline, we navigated the complexities of a brownfield environment, integrating new infrastructure seamlessly with the existing framework, while adhering to stringent technical, functional, and regulatory requirements. The result is a fully optimized, high-efficiency facility delivered on schedule, reflecting both our precision-driven approach and commitment to client satisfaction.

Global Indian Internation School, Anekal

The structure which is designed is not only environmentally responsible and resource efficient, but also integrates health, wellness and positive experiences. Only 20 percent of the ground area is built up, the rest is all open space. Every room is designed to ensure that there is sufficient natural light and ventilation. All efforts have been made to blur the difference between the indoor and outdoor. There is a free flow for movement of the children between the various activity centres both indoor and outdoor.

A number of initiatives have been undertaken to reduce the carbon footprint of the school.

- Rainwater, Recharge and Harvesting:

All the water from the roof are via a series of pipes taken to the recharge pits in the ground. The overflow pipe is connected to the harvesting tank. The water from the harvesting tank is used for landscaping. The entire drain and waste water from the toilets will be treated through the STP and stored in the overhead tanks for landscaping thus ensuring no wastage of water. - Day lighting:

The entire campus has been designed to provide natural light which has a positive effect on human health. If daylight is not available LED Lights are provided to ensure resource efficiency Indoor Environment Quality. (IEQ) Special attention has been given to ensure a high IEQ with reference to indoor air quality, temperature, lighting and selection of building materials. - Exercise:

The campus is designed to promote increased physical activity and exercise. Creating a walkable environment that connects children to all the green spaces and therapeutic landscapes thereby reducing absenteeism and improve well being.